We only have one planet and each of us is responsible to take care of it. Cranfield Foundry is one of the most modern foundries in Europe. We are taking advantage of advanced technology to help minimize the impact on the environment and health.

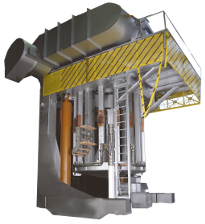

Induction Furnaces: At the heart of the Cranfield Foundry are electrically powered induction furnaces. In older foundries furnaces were fuelled by coal, coke, gas or other fossil fuels to melt the metal which created a great deal of emissions. The induction furnaces use electricity to melt the scrap metal at the optimum temperature which makes them much more environmentally friendly.

Other emissions: An induction furnace is sensitive to the type of material used to ensure a quality "melt" therefore, Cranfield Foundry is not using scrap materials contaminated with paint, oils, glues or other coatings. We must use "clean" scrap - bare metal. This significantly reduces the emissions during the melting process making it much easier to capture and filter any potential contamination with our state-of-the-art filtration system. In addition, the amount of "slag" is greatly reduced because of the "clean" metal used in the process.

Sand: The moulds that the liquid metal are poured into are made from silica sand mixed with bentonite clay (all natural materials) water is mixed in to help form the mould together to make a mould (much like building a sand castle on the beach) No other chemicals are added to this mix. Most of the water from the sand evaporates during the cooling process. Approximately 95 - 97% of the sand and bentonite are recycled in the foundry. When the sand cannot hold its form it is removed from the plant. This sand is safe to be used as an aggregate in the construction industry and is also used in municipal garbage dumps for "layering" over (regular household) garbage.